wire mesh screen manufacturer

Latest articles

wire mesh screen manufacturerGalvanized iron wire is widely used in construction, handicrafts, wire mesh, highway guardrail, product packaging and daily civilian and other fields.

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read Morewire mesh screen manufacturer

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read Morewire mesh screen manufacturer

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read More

wire mesh screen manufacturer1. PVC plastic coated barbed rope adopts flexible structure

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read More

wire mesh screen manufacturerGalvanized wire coating is galvanized, aluminum plated, coated with nylon or plastic, etc. Zinc is divided into thin coating of steel wire after plating and thick coating of galvanized steel wire after drawing. The mechanical properties of thick coating are reduced compared with smooth steel wire rope, which should be used in severe corrosion environment. It is more resistant to corrosion, wear and heat than galvanized wire rope, using the first plating and then drawing method of production. Coated nylon or plastic wire rope is divided into two kinds of coated rope and coated stock after the rope.

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read Morewire mesh screen manufacturer

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read More

wire mesh screen manufacturerStainless steel barbed rope in the way of corrosion is not very, because the surface is not treated but rely on its own raw materials for corrosion resistance, so there will be no chemical reaction. After a long time of use, it will not rust like the corrosion layer on the surface of hot dip galvanized barbed rope, because the internal material of stainless steel barbed rope is the same as the material on the surface. The most obvious difference in a short time is the cross section of this piece, hot dip galvanized barbed wire because of surface anticorrosion treatment, so there will be rust in the cross section of this piece, and stainless steel barbed wire because the internal raw materials and surface raw materials are consistent, so there is no such situation.

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read Morewire mesh screen manufacturer

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read More3, galvanized silk mesh binder transport, storage and use should be in accordance with the relevant provisions to adopt safety, fire prevention methods, so as to be more safe use.

wire mesh screen manufacturer...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read Morewire mesh screen manufacturer

...

wire mesh screen manufacturer 【wire mesh screen manufacturer】

Read More

Popular articles

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

Post time: 20-10-22In the purchase of barbed rope should be customer demand, so the amount of galvanized is different, then the two kinds of barbed rope and what is the difference, some customers need high zinc blade barbed rope, but high zinc blade barbed rope price to ordinary galvanized barbed rope price is more than 1000 yuan per ton, the two kinds of barbed rope products, the former is used in many aspects, such as the military, the government’s barbed rope, The latter is more for civilian use.

Latest articles

-

-

Post time: 12-07-22 -

In order to adapt to the living habits of different birds, ornamental cages can be roughly divided into two types of bird cages, namely cereal and insectivorous cages. Cereal bird cage with canary cage, yellow bird cage, wenbird cage, bird cage, hydrangea cage, insect-eating bird cage with thrush cage, chin cage, myna cage and so on.

-

Post time: 02-03-23 -

-

6, the use of special formula and special UV absorbent, no fading, no yellowing, no peeling, no cracking, no foaming, no moth, the use cycle can be more than 30 years.

Links

- Despite its significance, fire retardant duct tape remains a background player in our daily lives. Yet, its silent vigilance is what makes it so crucial. As we continue to advance technologically, the demand for safer materials grows alongside. Fire retardant duct tape stands as a testament to human innovation in the face of potential danger, a simple roll of tape with extraordinary capabilities that contributes to a safer world.

- 3. Anti-Slip Tape This tape is designed to provide extra traction on slippery surfaces, reducing the risk of slips and falls. It is commonly used in areas with high foot traffic, such as stairways, ramps, and walkways.

- Moreover, this tape is not just about its visual appeal; it is designed to withstand heavy foot traffic, extreme weather conditions, and even resist chemicals, ensuring its visibility and effectiveness over time. Its durability and versatility make it a go-to tool for numerous safety and organizational needs.

- In today's world, where safety is of utmost importance, fireproof tape has emerged as a versatile solution for various fire safety concerns. This specialized type of adhesive tape is designed to withstand extreme temperatures and prevent the spread of flames, making it an essential tool in industries ranging from construction to electronics manufacturing.

- 5. Flexibility High temperature insulation tape maintains its flexibility over a wide temperature range, allowing it to conform to uneven surfaces and withstand vibrations and impacts.

2. Stretch the tape Most amalgamating tapes come on a roll and need to be stretched before application. Gently stretch the tape to activate the adhesive properties.

In the realm of control boxes, diversity is critical. Each type is designed to fit the puzzle of specific needs and environments. Let’s explore some of the common varieties:

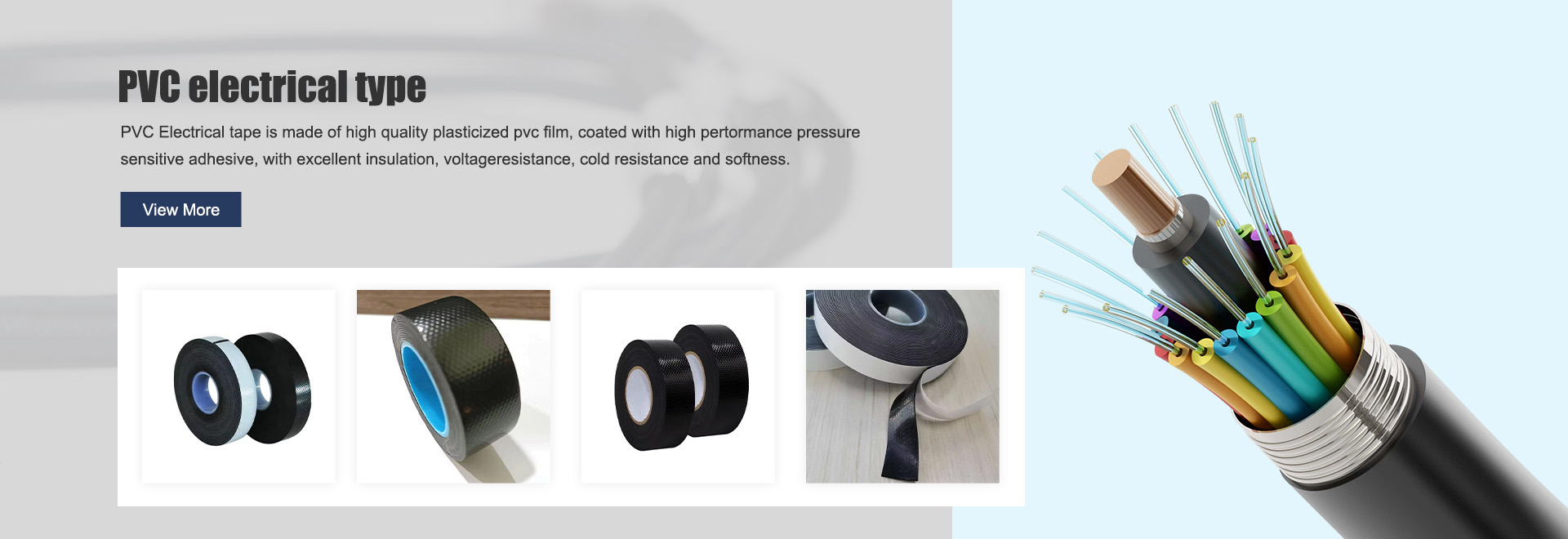

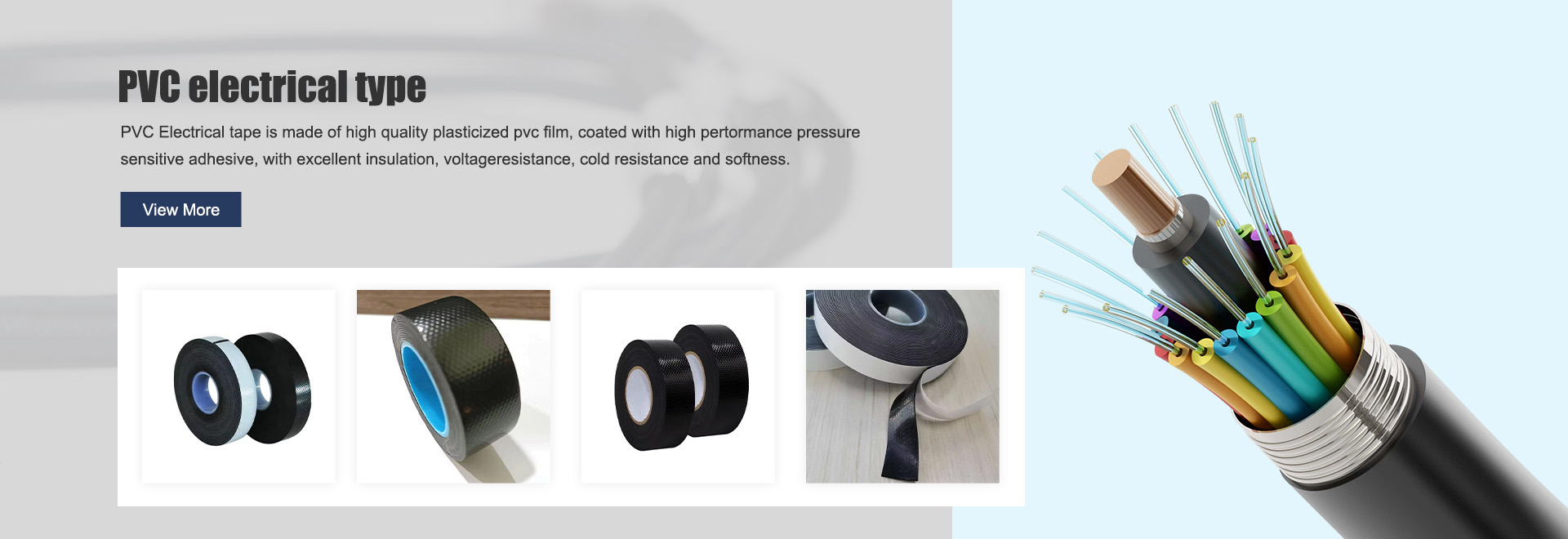

What is Black PVC Electrical Tape?

6. Convenient maintenance: the surface is not sticky, the surface does not stick to the hand, and does not adhere to the contacted surface;

Small Household Repairs

One of the key characteristics of PVC tape is its durability. It is resistant to moisture, chemicals, and UV light, making it suitable for both indoor and outdoor applications. Additionally, it can withstand a wide range of temperatures, which is essential for environments where electrical systems may experience significant thermal fluctuations.

Hot-melt rubber

It has a very high adhesive level and sticks to most smooth surfaces quickly.

Whether you're dealing with a leaky roof, a cracked aquarium, or a broken outdoor furniture, Flex Tape Waterproof Clear is the answer. Its versatility, durability, transparency, and ease of use make it a go-to product for all kinds of repair and sealing needs.

Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties

Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties Care must be taken to ensure that the tape is wrapped evenly and tightly, without any gaps or overlaps, to maximize its protective properties automotive wire harness wrapping tape.

automotive wire harness wrapping tape.Industrial Control Boxes

Overall, the 130C linerless rubber splicing tape is a versatile and reliable product that is suitable for a wide range of applications. Its high heat resistance, durability, and environmental benefits make it a popular choice among professionals in various industries. Whether you need to join rubber materials together, create a leak-proof seal, or provide insulation in high-temperature environments, this tape is a valuable tool to have in your arsenal. With its strength and versatility, the 130C linerless rubber splicing tape is a must-have for any business or professional looking for a reliable bonding solution.

One of the most common types of splicing tape is the clear adhesive tape. This tape is used to physically splice together two pieces of film, creating a seamless transition between them. It is essential for maintaining the continuity of a film and ensuring that the final product looks professional and polished.